It can help to remove the contaminants entered from the surface effortlessly. Airlocks must be held empty, content which include clothes, footwear addresses and many others. should not stored during the airlocks. I've observed it over and over in pharmaceuticals trying to keep these content in airlocks. In Pharmaceutical, Bio-Pharmaceutical and sterile manufacturing, the clear room surroundings is the key prerequisite for all manufacturing activity: without having a right motion mechanism & background atmosphere, no medicine could be created for client use. The intentions and purpose are the truth of steady, reliant, and compliant Procedure within a tightly managed and monitored setting. Limited Consumer Specifications or Style and design Philosophies needs to be written or inked down in advance of setting up Airlocks in cleanse rooms. The challenge for almost any High-quality unit is usually to define URS based upon regulatory considerations when the power exports an item in different regulatory regions.

Equipment airlocks, as being the title implies, are precisely made for transferring huge tools or equipment into cleanroom environments.

An notify ought to be offered to show that a person entryway is opened. It keeps the portion of contamination through the airlocks.

Contamination is often a fermenter’s worst nightmare. The airlock acts like a guardian, preserving destructive micro organism and yeasts at bay. This not merely makes certain the security of your respective fermented vegetables and also contributes to your consistency of the fermentation procedure.

The specialized storage or entry is strictly essential for the legit intent of enabling the usage of a certain assistance explicitly asked for via the subscriber or user, or for the only reason of carrying out the transmission of a communication around an electronic communications network. Tastes Choices

In oral reliable dosage type parts, we hold within the manufacturing place at more info unfavorable strain to stop our stream of powders. So significant checking of air pressure routine maintenance is needed in all places simply because any drop or increase in the force of any place may possibly lead to cross-contamination.

Containment facilities managing potent APIs or hazardous chemical compounds: Sink airlocks are widely used in high-containment facilities where strong APIs, harmful chemical compounds, or biological agents are processed.

As the identify indicates, this sort of airlock is usually a pressurized space that pushes the air out and into both of those the regions it protects. This sort of airlock makes a barrier among The 2 spaces it serves, Therefore protecting against cross contamination.

You'll find other types of strain differentials Utilized in airlocks, dependant upon what style of work is currently being done in the cleanroom. For example, bubble airlocks have the highest pressure In the airlock by itself, which pushes particles back check here into their respective locations.

The new thought is always that firms are developing multi-use production facilities capable of manufacturing two or maybe more goods at the same time. This refers to the scenario the place a producer of medicinal items produces two or maybe more items within the similar facility either concurrently or on a campaigned foundation.

As an example, in a bubble airlock, the airlock ought to preserve a higher stress than each adjoining rooms. In distinction, the airlock should preserve lower strain to entice contaminants in a sink airlock.

Deciding upon an acceptable container on your vegetable fermentation is important. Whether or not it’s a glass jar, ceramic crock, or focused fermentation vessel, assure it’s clear and totally free from any residues that could have an affect on the flavor within your ferment.

Regulatory Compliance: Superior Production Tactics (GMP) are essential in the pharmaceutical environment. Air locks enable us satisfy these regulations by supplying a secure, managed entry place for people today and materials into clean areas. It’s all about retaining issues Safe and sound and compliant!

Since airlocks and gowning rooms are equally essential concerning air classifications, they are often regarded as a similar. There are actually cases, nonetheless, when gowning takes place along with a alter of air classification will not. A case in point can be a multiproduct facility the place containment is crucial.

Edward Furlong Then & Now!

Edward Furlong Then & Now! Andrea Barber Then & Now!

Andrea Barber Then & Now! Mike Vitar Then & Now!

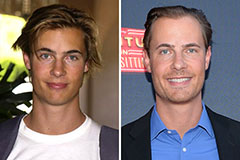

Mike Vitar Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Freddie Prinze Jr. Then & Now!

Freddie Prinze Jr. Then & Now!